top of page

Traditional Construction

Full floor with subgrades comprised of clay, silt, or loam soils

Sand selection dictates sand depth in the lowest-lying areas

Recessed Drain Lines

Used on projects with fine sands on clay, silt or loam soils

Deeper sand depth over the lowest lying drain lines lowers the perched water table

Typical Construction

Sand depth 4 - 6"

Recessed Drain Line

Sand depth 8 - 10"

Open Bottom

Used on projects with fine sands on a high percolating soil

The bottom can be left open or covered with a geotextile

All gravel sprayed with polymer - drain lines included

BBB layer ends in a termination strip or over a drain tile

Partial BBB

Partials can lead to cost savings on large bunkers

The bottom can be left open or covered with a geotextile

All gravel sprayed with polymer - drain lines included

BBB layer ends in a termination strip or over a drain tile

2" of BBB

approved gravel

BBB termination Strip

connected to 4" tile

Sand depth

4 - 6"

Geotextile liner

optional

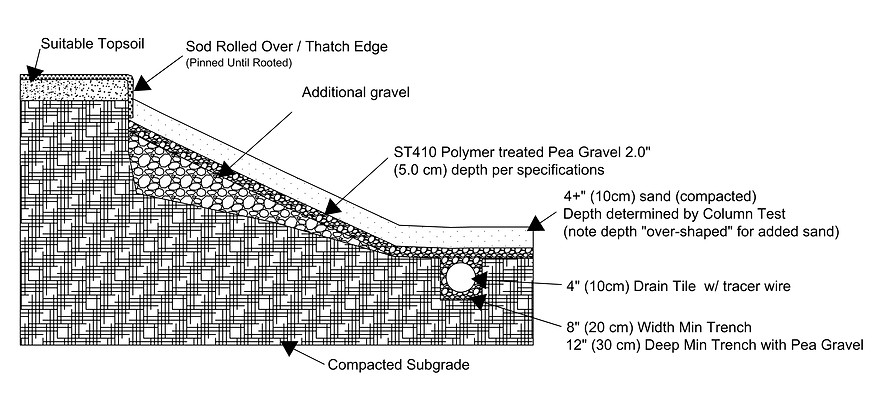

No Perch Drainage Trench

Deeper sand helps to alleviate "wet bottom"

Trench is in the lowest portion of the bunker

Drain tile in the trench may lay on or within gravel floor

BBB layer ends in a termination strip or over a drain tile

High Inflow

Used when water is diverted into the bunker

Additional BBB gravel or a larger stone can be used to handle the high inflow

Any areas with sheet should be addressed during construction

bottom of page